Dolphitech-Dolphicam2 > 复材探伤知识库 > 复合材料探伤问答 > Dolphicam2在复合材料超声波探伤中的分辨率是多少?

Dolphicam2在复合材料超声波探伤中的分辨率是多少?

作者:为复合材料探伤而生的Dolphicam2+实时3D成像相控阵探伤仪 发布时间:2024-10-18 11:06:58《Dolphicam2在复合材料超声波探伤中的分辨率是多少?》

仪器购买:135-0542-5410

检测服务:186-5324-2346

青岛纵横仪器有限公司,作为国内的无损检测设备提供商,一直致力于为客户提供高质量、高精度的检测设备。其中,Dolphicam2超声波探伤仪是公司的明星产品,广泛应用于复合材料的无损检测中。本文将重点讨论Dolphicam2在复合材料超声波探伤中的分辨率问题。

Qingdao Zongheng Instrument Co., Ltd., as a leading domestic provider of non-destructive testing equipment, has always been committed to providing customers with high-quality and high-precision testing equipment. Among them, the Dolphicam2 ultrasonic flaw detector is the company's star product, widely used in the non-destructive testing of composite materials. This article will focus on the resolution of the Dolphicam2 in ultrasonic flaw detection of composite materials.

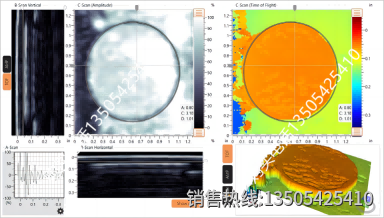

分辨率是超声波探伤设备的一个重要指标,它决定了设备能够检测到的最小缺陷尺寸。Dolphicam2采用了先进的超声波技术和高分辨率的探头,使其在复合材料探伤中具有出色的分辨率。具体来说,Dolphicam2的分辨率可以达到毫米级别,这意味着它能够清晰地显示出复合材料中微小的缺陷。

Resolution is an important indicator of ultrasonic flaw detection equipment, which determines the minimum defect size that the equipment can detect. Dolphicam2 adopts advanced ultrasonic technology and high-resolution probes, making it have excellent resolution in composite material flaw detection. Specifically, the resolution of Dolphicam2 can reach the millimeter level, which means that it can clearly show tiny defects in composite materials.

为了更直观地理解Dolphicam2的高分辨率特性,我们可以举几个实际应用中的例子。首先,在航空航天领域,复合材料被广泛应用于飞机机翼、机身等关键部位。这些部位的任何微小缺陷都可能对飞行安全构成严重威胁。通过使用Dolphicam2进行探伤,可以精确地检测出这些微小缺陷,从而及时进行修复,确保飞行安全。

To more intuitively understand the high-resolution characteristics of Dolphicam2, we can give a few examples of practical applications. Firstly, in the aerospace field, composite materials are widely used in key parts such as aircraft wings and fuselages. Any tiny defects in these parts can pose a serious threat to flight safety. By using Dolphicam2 for flaw detection, these tiny defects can be accurately detected, allowing timely repairs to ensure flight safety.

再比如,在汽车制造领域,复合材料也越来越多的被应用。汽车的车身、引擎盖等部位都可能采用复合材料制造。这些部位的质量直接关系到汽车的安全性和耐用性。通过使用Dolphicam2进行高精度的超声波探伤,可以有效地提高汽车的质量,减少因材料缺陷导致的安全隐患。

Another example is in the automotive manufacturing field, where composite materials are increasingly being used. Parts such as car bodies and hoods may be made of composite materials. The quality of these parts is directly related to the safety and durability of the vehicle. By using Dolphicam2 for high-precision ultrasonic flaw detection, the quality of the car can be effectively improved, reducing potential safety hazards caused by material defects.

除了航空航天和汽车制造领域,Dolphicam2还在其他许多领域发挥着重要作用。例如,在船舶制造中,复合材料被广泛应用于船体、甲板等部位。通过使用Dolphicam2进行探伤,可以确保这些部位的质量和安全性。此外,在风力发电、体育器材等领域,Dolphicam2也展现出了其高精度探伤的优势。

Besides the aerospace and automotive manufacturing fields, Dolphicam2 also plays an important role in many other areas. For example, in shipbuilding, composite materials are widely used in hulls, decks, and other parts. By using Dolphicam2 for flaw detection, the quality and safety of these parts can be ensured. Additionally, Dolphicam2 demonstrates its advantages in high-precision flaw detection in fields such as wind power generation and sports equipment.

那么,Dolphicam2是如何实现如此高的分辨率的呢?首先,它采用了高频超声波技术。高频超声波具有更短的波长,因此能够更容易地穿透复合材料并检测到微小的缺陷。其次,Dolphicam2配备了高分辨率的探头,能够接收到更微弱的反射信号,从而提高了探伤的精度和分辨率。

So, how does Dolphicam2 achieve such high resolution? Firstly, it adopts high-frequency ultrasonic technology. High-frequency ultrasonic waves have shorter wavelengths, making it easier to penetrate composite materials and detect tiny defects. Secondly, Dolphicam2 is equipped with a high-resolution probe that can receive weaker reflected signals, thereby improving the accuracy and resolution of flaw detection.

此外,Dolphicam2还采用了先进的信号处理技术。通过对接收到的超声波信号进行精确的分析和处理,Dolphicam2能够准确地识别出复合材料中的缺陷位置和大小。这种先进的信号处理技术也是实现高分辨率探伤的关键因素之一。

Furthermore, Dolphicam2 employs advanced signal processing technology. Through precise analysis and processing of the received ultrasonic signals, Dolphicam2 can accurately identify the location and size of defects in composite materials. This advanced signal processing technology is also one of the key factors in achieving high-resolution flaw detection.

总的来说,Dolphicam2在复合材料超声波探伤中的高分辨率特性得益于高频超声波技术、高分辨率探头以及先进的信号处理技术的综合应用。这些技术的结合使得Dolphicam2能够精确地检测出复合材料中的微小缺陷,为各行各业提供高质量的无损检测服务。

Overall, the high-resolution characteristics of Dolphicam2 in ultrasonic flaw detection of composite materials benefit from the combined application of high-frequency ultrasonic technology, high-resolution probes, and advanced signal processing technology. The combination of these technologies enables Dolphicam2 to accurately detect tiny defects in composite materials, providing high-quality non-destructive testing services to various industries.