Dolphitech-Dolphicam2 > 复材探伤知识库 > 复合材料探伤问答 > 如何使用Dolphicam2检测复合材料中的夹杂缺陷

如何使用Dolphicam2检测复合材料中的夹杂缺陷

作者:为复合材料探伤而生的Dolphicam2+实时3D成像相控阵探伤仪 发布时间:2024-10-18 11:51:55如何使用Dolphicam2检测复合材料中的夹杂缺陷?

仪器购买:135-0542-5410

检测服务:186-5324-2346

青岛纵横仪器有限公司,作为专业的无损检测设备提供商,一直致力于为客户提供高效、精准的检测解决方案。其中,Dolphicam2实时3D可视化复合材料专用相控阵探伤仪,作为公司的明星产品,以其出色的性能在复合材料检测领域崭露头角。下面,我们将详细介绍如何使用Dolphicam2来检测复合材料中的夹杂缺陷。

一、准备工作

首先,确保Dolphicam2探伤仪与计算机系统已正确连接,并检查设备是否处于正常工作状态。同时,对待检测的复合材料进行表面清洁,确保无油脂、灰尘等杂质,以免影响检测结果。

Preparation

Firstly, ensure that the Dolphicam2 flaw detector is correctly connected to the computer system, and check whether the equipment is in normal working condition. At the same time, clean the surface of the composite material to be tested to ensure that there are no impurities such as grease and dust, so as not to affect the test results.

二、参数设置

打开Dolphicam2的探伤软件,根据待检测复合材料的厚度、密度等参数,设置相应的扫描参数。这些参数包括发射频率、接收增益、时间窗口等,它们对检测结果的准确性和灵敏度至关重要。

Parameter Setting

Open the flaw detection software of Dolphicam2, and set the corresponding scanning parameters according to the thickness, density and other parameters of the composite material to be tested. These parameters, including emission frequency, reception gain, time window, etc., are crucial to the accuracy and sensitivity of the test results.

三、扫描模式选择

Dolphicam2提供了多种扫描模式,如2D扫描、3D扫描和深度扫描。根据待检测缺陷的深度和分布,选择合适的扫描模式。对于夹杂缺陷,通常建议使用3D扫描模式,以便更全面地了解缺陷的三维形态。

Scanning Mode Selection

Dolphicam2 provides multiple scanning modes, such as 2D scanning, 3D scanning, and depth scanning. Select the appropriate scanning mode based on the depth and distribution of the defects to be detected. For inclusion defects, it is generally recommended to use the 3D scanning mode to obtain a more comprehensive understanding of the three-dimensional shape of the defects.

四、开始检测

启动Dolphicam2的探头,对复合材料进行预扫描,以初步了解材料中可能存在的缺陷区域。在预扫描过程中,注意观察探伤仪的显示屏,记录异常信号的位置和强度。

Start Detection

Start the probe of Dolphicam2 and perform a pre-scan on the composite material to initially understand the potential defect areas in the material. During the pre-scan process, pay attention to observing the display screen of the flaw detector and record the location and intensity of abnormal signals.

五、数据采集与分析

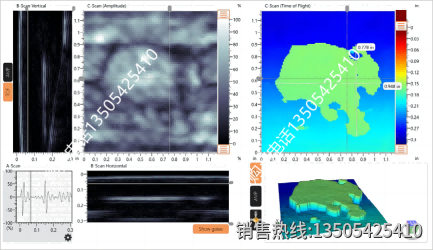

在正式扫描过程中,Dolphicam2的探头会采集大量的回波数据。这些数据将被导入计算机软件进行3D重建和可视化分析。通过观察重建后的三维图像,可以清晰地识别出夹杂缺陷的位置、大小和形状。

Data Acquisition and Analysis

During the formal scanning process, the probe of Dolphicam2 will collect a large amount of echo data. These data will be imported into computer software for 3D reconstruction and visualization analysis. By observing the reconstructed three-dimensional image, the location, size, and shape of the inclusion defects can be clearly identified.

六、缺陷评估与修复

根据3D可视化结果,对夹杂缺陷进行评估。如果缺陷对复合材料的结构性能产生严重影响,需要及时采取措施进行修复或更换存在缺陷的部件。同时,将检测结果记录在报告中,为后续的质量控制和改进提供依据。

Defect Evaluation and Repair

Evaluate the inclusion defects based on the 3D visualization results. If the defects have a serious impact on the structural performance of the composite material, prompt measures need to be taken to repair or replace the defective components. At the same time, record the test results in a report to provide a basis for subsequent quality control and improvement.

案例分享

以下是使用Dolphicam2检测复合材料中夹杂缺陷的几个成功案例:

Case Sharing

Here are a few successful cases of using Dolphicam2 to detect inclusion defects in composite materials:

案例一:在某航空公司的碳纤维复合材料机翼检测中,Dolphicam2成功识别出机翼内部一处夹杂缺陷,避免了潜在的安全隐患。

Case 1: In the inspection of carbon fiber composite wings for an airline, Dolphicam2 successfully identified an inclusion defect inside the wing, avoiding potential safety hazards.

案例二:一家汽车制造商在检测碳纤维车身部件时,利用Dolphicam2发现了部件中的夹杂物,及时进行了修复,确保了车身的质量。

Case 2: When inspecting carbon fiber body parts for an automobile manufacturer, Dolphicam2 was used to discover inclusions in the parts, which were then promptly repaired to ensure the quality of the vehicle body.

案例三:一家风电设备制造商在检测风力发电机叶片时,通过Dolphicam2的3D可视化功能,清晰地看到了叶片内部的夹杂缺陷,为后续的维修提供了有力支持。

Case 3: When inspecting wind turbine blades for a wind power equipment manufacturer, the 3D visualization function of Dolphicam2 allowed clear identification of inclusion defects inside the blades, providing strong support for subsequent maintenance.

青岛纵横仪器有限公司始终致力于为客户提供最先进的无损检测设备和专业的技术支持。通过不断的技术创新和产品升级,我们将继续为客户提供更加优质、高效的无损检测解决方案,助力各行各业的安全生产和质量控制。如需了解更多关于Dolphicam2的信息,请随时联系我们。

Qingdao Zongheng Instrument Co., Ltd. has always been committed to providing customers with the most advanced non-destructive testing equipment and professional technical support. Through continuous technological innovation and product upgrades, we will continue to provide customers with higher-quality and more efficient non-destructive testing solutions, assisting various industries in safety production and quality control. For more information about Dolphicam2, please feel free to contact us.