Dolphitech-Dolphicam2 > 复材探伤知识库 > 复合材料探伤问答 > 使用Dolphicam2进行超声波探伤时,如何选择合适的探头频率?

使用Dolphicam2进行超声波探伤时,如何选择合适的探头频率?

作者:为复合材料探伤而生的Dolphicam2+实时3D成像相控阵探伤仪 发布时间:2024-10-18 11:21:19使用Dolphicam2进行超声波探伤时,如何选择合适的探头频率?

When using Dolphicam2 for ultrasonic inspection, how do we choose the appropriate probe frequency?

仪器购买:135-0542-5410

检测服务:186-5324-2346

在进行超声波探伤时,选择合适的探头频率是至关重要的。探头频率的选择直接影响到探伤的准确性和可靠性。

The selection of probe frequency is crucial as it directly affects the accuracy and reliability of the ultrasonic inspection.

首先,我们需要了解什么是探头频率。简单来说,探头频率指的是探头发射和接收超声波的频率,通常以千赫兹(kHz)或兆赫兹(MHz)表示。

Firstly, it's important to understand what probe frequency is. In simple terms, it refers to the frequency of ultrasonic waves emitted and received by the probe, typically expressed in kilohertz (kHz) or megahertz (MHz).

一、考虑材料的特性

Material Properties

不同的材料对超声波的传播有不同的影响。例如,一些材料可能更容易让高频超声波衰减,而另一些材料则可能对低频超声波有更好的透射性。

Different materials have varying effects on the propagation of ultrasonic waves. For example, some materials may attenuate high-frequency waves more easily, while others may allow better transmission of low-frequency waves.

对于金属材料,如钢铁,通常使用较低频率的探头,如1-5 MHz,因为这些频率可以更好地穿透材料。

For metallic materials like steel, lower frequency probes, such as 1-5 MHz, are commonly used as they provide better penetration through the material.

而对于一些复合材料或更薄的材料,可能需要使用更高频率的探头以获得更高的分辨率。

On the other hand, for some composite materials or thinner sections, higher frequency probes may be necessary to achieve higher resolution.

二、考虑探伤的深度和精度要求

Inspection Depth and Accuracy Requirements

探伤的深度和精度是选择探头频率时需要权衡的两个关键因素。

Depth and accuracy of inspection are two key factors that need to be balanced when selecting probe frequency.

高频探头通常提供更高的分辨率,能够检测到更小的缺陷,但它们的穿透能力相对较弱。因此,如果需要探测较深处的缺陷,可能需要选择低频探头。

High-frequency probes typically offer higher resolution and can detect smaller defects, but they have relatively poorer penetration. Therefore, if deeper defects need to be detected, lower frequency probes may be chosen.

相反,如果主要关注材料表面或近表面的缺陷,并且需要高精度的测量结果,那么高频探头是更好的选择。

Conversely, if the focus is on surface or near-surface defects, and high-precision measurements are required, high-frequency probes would be a better choice.

三、实例分析

Case Studies

为了更好地理解如何选择探头频率,以下是一些具体的应用实例。

To better understand how to choose probe frequency, here are some specific application examples.

例一:检测厚钢板中的缺陷

Example 1: Detecting Defects in Thick Steel Plates

对于厚钢板,我们可能需要使用低频探头,如2 MHz,以确保超声波能够穿透整个材料厚度,从而检测到内部的缺陷。

For thick steel plates, a low-frequency probe such as 2 MHz may be used to ensure that the ultrasonic waves can penetrate the full thickness of the material and detect internal defects.

例二:检测薄铝板中的微小裂纹

Example 2: Detecting Micro-cracks in Thin Aluminum Plates

对于薄铝板中的微小裂纹检测,我们可能需要使用高频探头,如10 MHz或更高,以获得足够的分辨率来识别这些微小缺陷。

For detecting micro-cracks in thin aluminum plates, a high-frequency probe, such as 10 MHz or higher, may be necessary to achieve sufficient resolution to identify these small defects.

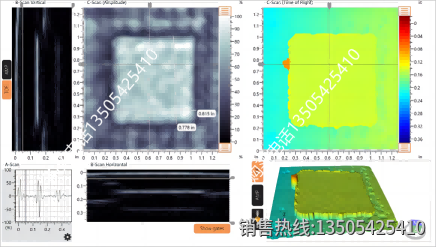

综上所述,选择合适的探头频率是确保Dolphicam2超声波探伤准确性和可靠性的关键步骤。通过考虑材料的特性、探伤的深度和精度要求,以及参考具体的应用实例,我们可以做出明智的选择。

In summary, selecting the appropriate probe frequency is a crucial step to ensure the accuracy and reliability of ultrasonic inspection using Dolphicam2 By considering material properties, inspection depth and accuracy requirements, and referring to specific application examples, we can make informed choices.