Dolphitech-Dolphicam2 > 复材探伤知识库 > 复合材料探伤问答 > 如何通过Dolphicam2分析复合材料中的缺陷类型?

如何通过Dolphicam2分析复合材料中的缺陷类型?

作者:为复合材料探伤而生的Dolphicam2+实时3D成像相控阵探伤仪 发布时间:2024-10-18 11:31:57如何通过Dolphicam2分析复合材料中的缺陷类型?

How to Analyze Defect Types in Composite Materials with Dolphicam2?

仪器购买:135-0542-5410

检测服务:186-5324-2346

复合材料在现代工业中的应用日益广泛,从航空航天到汽车制造,再到新能源领域,其优异的性能备受青睐。然而,复合材料在制造和使用过程中难免会出现各种缺陷,这些缺陷若不及时发现和处理,将严重影响材料的性能和使用安全。青岛纵横仪器有限公司作为专业的无损检测设备提供商,其Dolphicam2相控阵探伤仪在复合材料缺陷检测方面表现出色。本文将详细介绍如何通过Dolphicam2分析复合材料中的缺陷类型。

Composite materials are increasingly used in modern industries, from aerospace to automobile manufacturing, and even in the new energy sector, due to their excellent performance. However, various defects can occur during the manufacturing and use of these materials. If not detected and addressed in a timely manner, these defects can seriously affect the performance and safety of the materials. As a professional provider of non-destructive testing equipment, Qingdao Zongheng Instrument Co., Ltd. excels in detecting defects in composite materials with its Dolphicam2 phased array flaw detector. This article will detail how to analyze defect types in composite materials using Dolphicam2.

在进行复合材料缺陷检测前,需要对Dolphicam2进行正确的设置和校准。这包括选择合适的探头、调整扫描参数以及确保设备与被测材料的良好耦合。青岛纵横仪器有限公司的工程师团队拥有丰富的经验,可以为客户提供专业的技术支持和培训,确保检测结果的准确性和可靠性。

Before conducting defect detection in composite materials, it is necessary to properly set up and calibrate the Dolphicam2. This includes selecting the appropriate probe, adjusting scanning parameters, and ensuring good coupling between the device and the material under test. The engineering team at Qingdao Zongheng Instrument Co., Ltd. has extensive experience and can provide professional technical support and training to customers, ensuring the accuracy and reliability of test results.

使用Dolphicam2进行复合材料缺陷检测时,常见的缺陷类型包括分层、脱粘、孔隙和夹杂等。这些缺陷的产生原因多种多样,如制造工艺不当、材料老化或外力损伤等。Dolphicam2通过高精度的超声波扫描,能够捕捉到这些缺陷的细微变化,并以直观的图像形式展示出来。

When using Dolphicam2 for defect detection in composite materials, common defect types include delamination, debonding, voids, and inclusions. These defects can arise from various reasons such as improper manufacturing processes, material aging, or external damage. Dolphicam2, through high-precision ultrasonic scanning, can capture subtle changes in these defects and display them in intuitive graphical form.

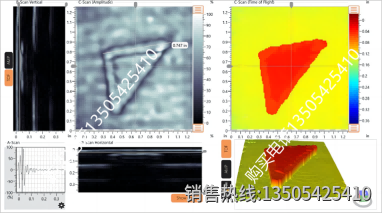

针对不同类型的缺陷,Dolphicam2提供了多种分析模式。例如,对于分层缺陷,可以通过观察扫描图像中的反射波形态和强度来判断分层的程度和位置;对于脱粘缺陷,则可以通过分析回波信号的连续性和衰减情况来确定脱粘的范围和严重程度。此外,Dolphicam2还具备3D可视化功能,可以更加直观地展示缺陷的三维形态和分布情况。

Dolphicam2 offers multiple analysis modes for different types of defects. For example, in the case of delamination defects, the degree and location of delamination can be determined by observing the morphology and intensity of reflected waves in the scanned image; for debonding defects, the scope and severity of debonding can be determined by analyzing the continuity and attenuation of echo signals. Additionally, Dolphicam2 is equipped with 3D visualization capabilities, which can more intuitively display the three-dimensional shape and distribution of defects.

举个例子,某航空航天企业在进行碳纤维复合材料机翼的检测时,发现了一处疑似分层缺陷。使用Dolphicam2进行扫描后,工程师通过观察扫描图像和3D可视化结果,迅速确定了分层缺陷的具体位置和大小。随后,企业及时采取了修复措施,避免了可能的安全隐患。

For instance, an aerospace company detected a suspected delamination defect during the inspection of a carbon fiber composite wing. After scanning with Dolphicam2, engineers quickly identified the specific location and size of the delamination defect by observing the scanned images and 3D visualization results. The company then promptly took remedial measures to avoid potential safety hazards.

除了分层缺陷外,Dolphicam2在检测其他类型的缺陷时也表现出色。例如,在检测孔隙缺陷时,可以通过分析扫描图像中的回声强度来判断孔隙的大小和分布;在检测夹杂缺陷时,则可以通过观察异常回声的形态和位置来确定夹杂物的性质和来源。

Apart from delamination defects, Dolphicam2 also excels in detecting other types of defects. For instance, when detecting void defects, the size and distribution of voids can be determined by analyzing echo intensity in the scanned images; when detecting inclusion defects, the nature and source of inclusions can be identified by observing the morphology and location of abnormal echoes.

青岛纵横仪器有限公司不仅提供先进的检测设备,还致力于为客户提供全方位的技术支持和服务。公司拥有一支专业的工程师团队,具备丰富的实践经验和深厚的理论知识,可以为客户提供从设备选型、安装调试到操作培训、故障排除等一站式服务。

Qingdao Zongheng Instrument Co., Ltd. not only provides advanced testing equipment but also strives to offer comprehensive technical support and services to customers. The company has a professional team of engineers with rich practical experience and deep theoretical knowledge, capable of providing customers with one-stop services from equipment selection, installation, and debugging to operation training and troubleshooting.

总之,通过Dolphicam2相控阵探伤仪的高精度扫描和直观的可视化分析,可以更加准确、快速地识别复合材料中的缺陷类型。青岛纵横仪器有限公司将继续致力于为客户提供更加先进、便捷的无损检测解决方案,为复合材料的安全应用保驾护航。

In summary, through the high-precision scanning and intuitive visualization analysis of the Dolphicam2 phased array flaw detector, defect types in composite materials can be identified more accurately and quickly. Qingdao Zongheng Instrument Co., Ltd. will continue to strive to provide customers with more advanced and convenient non-destructive testing solutions, escorting the safe application of composite materials.