Dolphitech-Dolphicam2 > 复材探伤知识库 > 复合材料探伤问答 > Dolphicam2能否实现复合材料的三维检测?

Dolphicam2能否实现复合材料的三维检测?

作者:为复合材料探伤而生的Dolphicam2+实时3D成像相控阵探伤仪 发布时间:2024-10-18 11:44:17Dolphicam2能否实现复合材料的三维检测?

仪器购买:135-0542-5410

检测服务:186-5324-2346

一、引言

随着复合材料在航空航天、汽车、船舶等领域的广泛应用,对其质量和性能的检测需求也日益增长。传统的二维检测方法已无法满足复杂结构内部缺陷的精准检测。因此,三维检测技术应运而生,成为行业发展的必然趋势。青岛纵横仪器有限公司作为专业的无损检测设备提供商,其Dolphicam2探伤仪备受关注。本文旨在探讨Dolphicam2是否能够实现复合材料的三维检测,并分析其在实际应用中的优势与局限性。

Introduction

With the widespread application of composite materials in aerospace, automotive, shipping and other fields, the demand for quality and performance testing has also been growing. Traditional two-dimensional detection methods can no longer meet the precise detection of internal defects in complex structures. Therefore, three-dimensional detection technology has emerged as an inevitable trend in the development of the industry. As a professional provider of non-destructive testing equipment, Qingdao Zongheng Instrument Co., Ltd.'s Dolphicam2 flaw detector has attracted much attention. This article aims to explore whether Dolphicam2 can achieve three-dimensional detection of composite materials, and analyze its advantages and limitations in practical applications.

二、Dolphicam2技术原理简介

Dolphicam2探伤仪采用先进的相控阵技术,通过控制多个超声换能器的发射和接收时间,实现对复合材料内部结构的精准扫描。该技术具有高分辨率、高灵敏度和实时成像等特点,为复合材料的三维检测提供了有力支持。

Brief Introduction to Dolphicam2 Technology Principles

The Dolphicam2 flaw detector adopts advanced phased array technology, which achieves precise scanning of the internal structure of composite materials by controlling the transmission and reception time of multiple ultrasonic transducers. This technology, featuring high resolution, high sensitivity, and real-time imaging, provides strong support for three-dimensional detection of composite materials.

三、Dolphicam2在复合材料三维检测中的应用

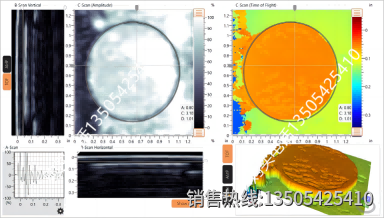

实时3D成像:Dolphicam2能够实时生成复合材料的3D图像,清晰展示材料内部的层次结构和缺陷形态。这有助于检测人员快速定位缺陷并评估其严重程度。

定量分析与缺陷识别:通过Dolphicam2的三维数据,可以对复合材料内部的缺陷进行定量分析和自动识别。例如,利用软件算法计算缺陷的体积、形状和位置等参数,为后续的修复工作提供准确依据。

复杂结构检测:对于具有复杂曲率或异形结构的复合材料部件,Dolphicam2的柔性探头和三维扫描能力使其能够轻松应对各种检测挑战。

Application of Dolphicam2 in Three-Dimensional Detection of Composite Materials

Real-time 3D Imaging: Dolphicam2 can generate real-time 3D images of composite materials, clearly showing the internal layered structure and defect morphology of the materials. This helps inspectors quickly locate defects and evaluate their severity.

Quantitative Analysis and Defect Identification: Through Dolphicam2's three-dimensional data, quantitative analysis and automatic identification of defects within composite materials can be performed. For example, software algorithms can be used to calculate parameters such as defect volume, shape, and location, providing an accurate basis for subsequent repair work.

Complex Structure Detection: For composite material components with complex curvatures or special shapes, Dolphicam2's flexible probes and three-dimensional scanning capabilities allow it to easily handle various detection challenges.

四、Dolphicam2三维检测的优势与局限性

优势:

高精度与高分辨率,确保检测结果的准确性。

实时成像功能,提高检测效率。

强大的数据分析与处理能力,便于后续的质量评估与修复工作。

局限性:

对操作人员的技能要求较高,需要专业的培训。

在某些极端条件下(如高温、高压),设备的性能可能受到影响。

对于部分特殊类型的复合材料,可能需要定制化的检测方案。

Advantages and Limitations of Dolphicam2 Three-Dimensional Detection

Advantages:

High precision and resolution ensure the accuracy of detection results.

Real-time imaging function improves detection efficiency.

Strong data analysis and processing capabilities facilitate subsequent quality assessment and repair work.

Limitations:

Higher skill requirements for operators, requiring professional training.

Equipment performance may be affected under certain extreme conditions (such as high temperature and high pressure).

Customized detection solutions may be required for some special types of composite materials.

五、结论与展望

综上所述,Dolphicam2探伤仪在复合材料的三维检测方面具有显著优势,能够满足复杂结构内部缺陷的精准检测需求。然而,在实际应用中仍需关注其局限性,并采取相应的改进措施。未来,随着技术的不断进步和创新,期待Dolphicam2在复合材料检测领域发挥更大的作用,为行业的发展贡献力量。

Conclusion and Prospects

In summary, the Dolphicam2 flaw detector has significant advantages in the three-dimensional detection of composite materials, able to meet the precise detection needs of internal defects in complex structures. However, in practical applications, it is still necessary to pay attention to its limitations and take corresponding improvement measures. In the future, with continuous technological progress and innovation, it is expected that Dolphicam2 will play a greater role in the field of composite material detection, contributing to the development of the industry.