Dolphitech-Dolphicam2 > 复材探伤知识库 > 复合材料探伤问答 > Dolphicam2能否检测复合材料中的微小裂纹?

Dolphicam2能否检测复合材料中的微小裂纹?

作者:为复合材料探伤而生的Dolphicam2+实时3D成像相控阵探伤仪 发布时间:2024-10-18 08:29:38Dolphicam2能否检测复合材料中的微小裂纹?

Can Dolphicam2 Detect Micro-cracks in Composite Materials?

仪器购买:135-0542-5410

检测服务:186-5324-2346

随着科技的飞速发展,复合材料在航空航天、汽车、船舶等诸多领域得到了广泛应用。然而,复合材料在制造和使用过程中可能会产生微小裂纹,这些裂纹若不及时发现和处理,将对材料的性能和安全性构成严重威胁。因此,采用先进的无损检测设备对复合材料进行定期检测显得尤为重要。青岛纵横仪器有限公司作为专业的无损检测设备提供商,其研发的Dolphicam2相控阵探伤仪在复合材料微小裂纹检测方面展现出卓越的性能。

With the rapid development of technology, composite materials have been widely used in many fields such as aerospace, automotive, and shipping. However, micro-cracks may occur during the manufacture and use of composite materials. If these cracks are not detected and treated in a timely manner, they will pose a serious threat to the performance and safety of the materials. Therefore, it is particularly important to use advanced non-destructive testing equipment for regular inspection of composite materials. As a professional provider of non-destructive testing equipment, Qingdao Zongheng Instrument Co., Ltd. has developed the Dolphicam2 phased array flaw detector, which exhibits excellent performance in detecting micro-cracks in composite materials.

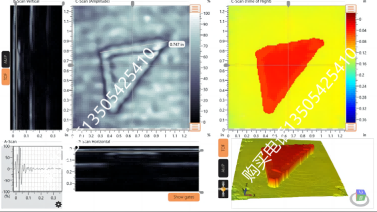

复合材料中的微小裂纹由于其尺寸小、隐蔽性强,传统的检测方法往往难以发现。Dolphicam2相控阵探伤仪采用了先进的实时3D成像技术,能够高精度地捕捉到复合材料内部的微小缺陷。其工作原理是通过发射超声波并接收回波信号,对材料内部结构进行成像分析,从而准确识别出裂纹、分层、脱粘等各类缺陷。

Due to their small size and strong concealment, micro-cracks in composite materials are often difficult to detect using traditional methods. The Dolphicam2 phased array flaw detector employs advanced real-time 3D imaging technology, which can capture micro-defects inside composite materials with high precision. Its working principle is to emit ultrasonic waves and receive echo signals to perform imaging analysis of the internal structure of the material, thereby accurately identifying various defects such as cracks, delamination, and debonding.

在实际应用中,Dolphicam2相控阵探伤仪展现出了显著的优势。首先,其操作简便,60秒即可完成从开箱到测试的全过程,大大提高了检测效率。其次,该设备具有经济实用的特点,维护成本低,适合各类企业长期使用。此外,Dolphicam2还配备了多种规格的探头,可适应不同形状和尺寸的复合材料检测需求。

In practical applications, the Dolphicam2 phased array flaw detector has demonstrated significant advantages. Firstly, it is easy to operate, and the entire process from unpacking to testing can be completed in 60 seconds, greatly improving detection efficiency. Secondly, the equipment is economical and practical, with low maintenance costs, suitable for long-term use by various enterprises. Furthermore, Dolphicam2 is equipped with multiple probes of different specifications, which can adapt to the detection requirements of composite materials of various shapes and sizes.

举个例子,在航空航天领域,碳纤维复合材料被广泛应用于飞机机翼、机身等部位。这些部位在飞行过程中承受着巨大的压力和温度变化,容易产生微小裂纹。通过使用Dolphicam2相控阵探伤仪进行定期检测,可以及时发现并处理这些裂纹,确保飞行安全。

For example, in the aerospace field, carbon fiber composite materials are widely used in aircraft wings, fuselages, and other parts. These parts are subjected to tremendous pressure and temperature changes during flight, which can easily lead to micro-cracks. Regular inspection using the Dolphicam2 phased array flaw detector can timely detect and address these cracks, ensuring flight safety.

同样,在汽车制造领域,复合材料也被广泛用于车身、引擎盖等部位。这些部位的微小裂纹若不及时发现,可能会导致车辆在使用过程中出现安全隐患。Dolphicam2相控阵探伤仪能够快速准确地检测出这些裂纹,为汽车制造商提供有力的质量保障。

Similarly, in the automotive manufacturing field, composite materials are also widely used in body panels, hoods, and other parts. If micro-cracks in these parts are not detected in a timely manner, they may pose safety hazards during vehicle use. The Dolphicam2 phased array flaw detector can quickly and accurately detect these cracks, providing a strong quality guarantee for automobile manufacturers.

除了航空航天和汽车制造领域外,Dolphicam2相控阵探伤仪在船舶、风电等行业的复合材料检测中也发挥着重要作用。其强大的检测功能和广泛的适用性使得它成为无损检测领域的佼佼者。

Besides the aerospace and automotive manufacturing fields, the Dolphicam2 phased array flaw detector also plays a vital role in the detection of composite materials in industries such as shipping and wind power. Its powerful detection capabilities and wide applicability make it a leader in the field of non-destructive testing.

总之,青岛纵横仪器有限公司研发的Dolphicam2相控阵探伤仪在复合材料微小裂纹检测方面表现出色。其先进的实时3D成像技术、简便的操作方式以及广泛的适用性使得它成为各类企业在进行复合材料无损检测时的设备。通过使用Dolphicam2,企业可以及时发现并处理复合材料中的微小裂纹,确保产品质量和安全性能达到标准。

In summary, the Dolphicam2 phased array flaw detector developed by Qingdao Zongheng Instrument Co., Ltd. excels in detecting micro-cracks in composite materials. Its advanced real-time 3D imaging technology, simple operation, and wide applicability make it the preferred equipment for various enterprises when conducting non-destructive testing of composite materials. By using Dolphicam2, enterprises can timely detect and address micro-cracks in composite materials, ensuring that product quality and safety performance meet the highest standards.

当然,Dolphicam2相控阵探伤仪的出色表现离不开青岛纵横仪器有限公司在无损检测领域多年的技术积累和创新精神。公司拥有一支专业的技术团队,致力于为客户提供高质量的无损检测设备和完善的售后服务。未来,青岛纵横仪器有限公司将继续秉承“质量、客户至上”的理念,不断推出更多先进的无损检测设备,为复合材料行业的发展贡献力量。

Of course, the excellent performance of the Dolphicam2 phased array flaw detector is inseparable from the many years of technical accumulation and innovative spirit of Qingdao Zongheng Instrument Co., Ltd. in the field of non-destructive testing. The company has a professional technical team dedicated to providing customers with high-quality non-destructive testing equipment and comprehensive after-sales service. In the future, Qingdao Zongheng Instrument Co., Ltd. will continue to uphold the concept of "quality first, customer first" and introduce more advanced non-destructive testing equipment to contribute to the development of the composite materials industry.

此外,针对复合材料微小裂纹检测的需求,青岛纵横仪器有限公司还提供了一系列专业的检测服务。公司拥有一支经验丰富的检测团队,可以根据客户的实际需求相应的检测方案,并提供准确的检测结果和详细的分析报告。这些服务不仅帮助客户及时发现和处理复合材料中的微小裂纹,还为客户提供了有力的技术支持和解决方案。

In addition to meeting the demand for micro-crack detection in composite materials, Qingdao Zongheng Instrument Co., Ltd. also provides a series of professional testing services. The company has an experienced testing team that can develop customized testing solutions based on customers' actual needs and provide accurate test results and detailed analysis reports. These services not only help customers timely detect and address micro-cracks in composite materials but also provide them with strong technical support and solutions.

值得一提的是,青岛纵横仪器有限公司在为客户提供优质产品和服务的同时,还注重与客户建立良好的合作关系。公司秉承“诚信、专业、高效”的服务理念,竭诚为每一位客户提供全方位的支持和帮助。通过与客户的紧密合作,青岛纵横仪器有限公司不仅赢得了客户的信任和赞誉,也为自身的发展奠定了坚实的基础。

It's worth mentioning that while providing high-quality products and services to customers, Qingdao Zongheng Instrument Co., Ltd. also focuses on establishing good cooperative relationships with them. Adhering to the service philosophy of "integrity, professionalism, and efficiency", the company sincerely provides all-round support and assistance to every customer. Through close cooperation with customers, Qingdao Zongheng Instrument Co., Ltd. has not only gained their trust and praise but also laid a solid foundation for its own development.

在总结Dolphicam2相控阵探伤仪在复合材料微小裂纹检测方面的应用时,我们可以得出以下结论:首先,Dolphicam2凭借其先进的实时3D成像技术能够高精度地捕捉到复合材料内部的微小缺陷;其次,该设备操作简便、经济实用且广泛适用;最后,青岛纵横仪器有限公司提供的专业检测服务和全方位支持进一步增强了Dolphicam2的市场竞争力。因此,对于需要进行复合材料微小裂纹检测的企业来说,选择Dolphicam2无疑是一个明智的决策。

When summarizing the application of the Dolphicam2 phased array flaw detector in detecting micro-cracks in composite materials, we can draw the following conclusions: Firstly, Dolphicam2 can capture micro-defects inside composite materials with high precision thanks to its advanced real-time 3D imaging technology; secondly, the equipment is easy to operate, economical, practical, and widely applicable; finally, the professional testing services and comprehensive support provided by Qingdao Zongheng Instrument Co., Ltd. further enhance the market competitiveness of Dolphicam2. Therefore, for enterprises that need to conduct micro-crack detection in composite materials, choosing Dolphicam2 is undoubtedly a wise decision.